Handmade sandwich panel and mechanized sandwich panel

Handmade sandwich panel and mechanized sandwich panel is considered a very professional term, only those in the sandwich panel industry immersed in many years to understand the mystery. In addition, many industry veterans believe that the hand sandwich panel and the mechanism of the sandwich panel belongs to the field of clean room panel, in fact, in the cold storage panel professional also divided into handmade sandwich panel and mechanized of the sandwich panel.

Clean room panel

For some people who have been working in clean rooms for a long time, especially for organizations that produce and install clean room panel, handmade sandwich panel and machanized sandwich panel are too familiar, which we call handmade clean room panel and machanized clean room panel.

Handmade clean room panel

Definition of Handmade clean room panel

The handmade clean room panel uses galvanized steel frame as the enclosure structure, pre-coated steel sheet, stainless steel sheet or aluminum sheet as the double-layer surface, rock wool, hollow glass magnesium or rock wool glass magnesium composite panel, PU or EPS and other materials as infiller.

Advantages of Handmade clean room panel

Handmade clean room panels offer several distinct advantages over mass-produced alternatives, particularly for complex or specialized environments.

Superior Customization & Flexibility

Handmade clean room panels are typically designed to fit irregular spaces and complex geometries, or to seamlessly integrate with existing structural members, pipes, ducts or equipment that machined clean panels cannot accommodate. Handmade clean room panels can be customized to easily accommodate special requirements such as special wall thicknesses, integrated services (wiring, ducting within the panel), custom window locations or special channel configurations.

Seamless integration and reduced joints

Handmade clean room panels reduce seams between panels, creating longer continuous sections or entire surfaces than connecting multiple standard size machine clean room panels, thereby reducing potential leak paths. Handmade clean room panels fit perfectly with the building, blending perfectly with the existing building structure, floors, ceilings and adjacent rooms, minimizing gaps and ensuring a continuous and clean enclosure.

Precise precision control

Handmade clean room panel require experienced craftsmen to produce, focusing on fit, surface treatment and air tightness. The attention to detail is usually higher. Handmade clean room panels are built on site or precisely customized according to on-site measurements, making the seams and joints tighter, which is critical for pollution control and pressure differentials.

Connection of handmade clean room panel

The connection of handmade clean room panel requires connecting fittings, both clean room ceiling panel and clean room partition panel need corresponding fittings, which are like various connectors to connect handmade clean panels perfectly without gaps.

Mechanized clean room panel

Definition of mechanized clean room panel

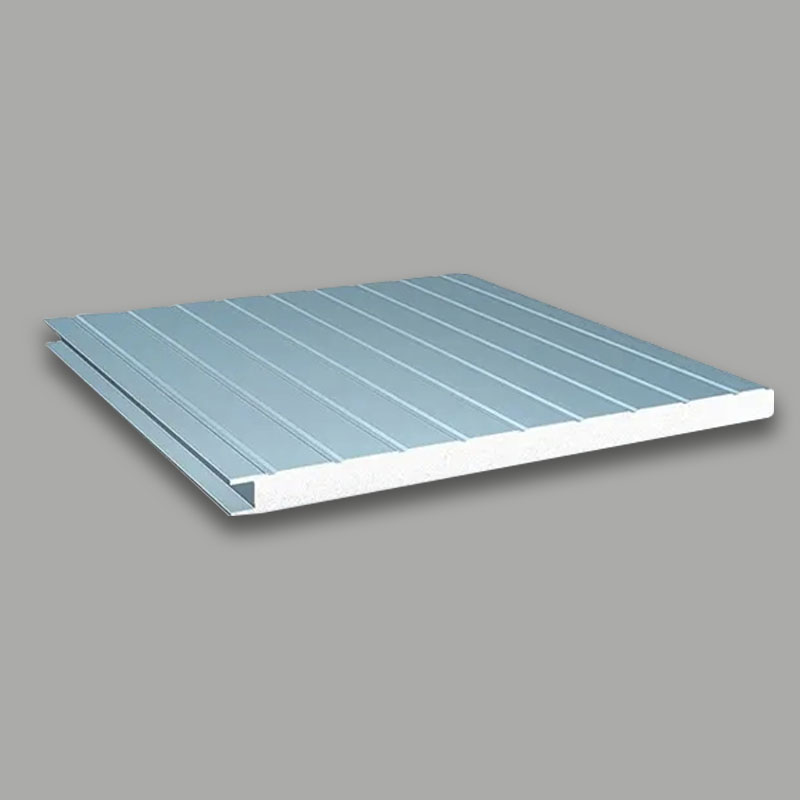

As suggested from the name, mechanized clean room panel is made 100% by a machine, without any manual operation, including pre-coated sheet cutting, bending, glue application, infill placement, pre-coated double-side sheets and infill compression.

Advantage of mechanized clean room panel

Cost advantages

Compared with handmade sandwich panels, the price of machine-made sandwich panels is lower. Since machine-made sandwich panels are all produced by machines without manual operation, including all processes, the production cost is relatively low.

Fast installation

Since the connection of the clean room board is based on its own male and female interfaces, no additional connectors are required, so the installation speed will be faster. The clean room board is generally used in large clean room buildings.

On-site opening

Another advantage of mechanized clean room panel is that installer can make cutouts for cleanroom windows or cleanroom doors at site, don’t worry to cut the panel seams. However, for hand-made panel, all dimensions must be accurate, the positions of doors and windows are fixed and cutting is not allowed on site, particularly cutting happen on the panel seams.

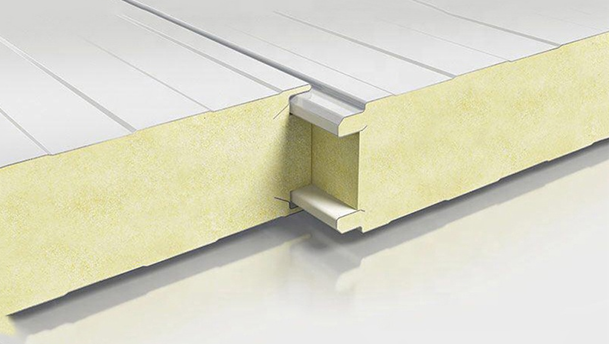

Connection of mechanized clean room panel

For the connection of two mechanized clean room panels, nothing is required, as you can see from the above image, the machine-made sandwich panel has male and female sides at two sides. When installation on site, just push one panel into another panel.

Cold storage panel

Cold storage panel is also divided into Handmade cold storage panel and mechanical cold storage panel. The definition is similar to that of clean room panel, and their advantages and disadvantages are similar to those of clean room panel. The difference that can be made with the cold storage panel is the connection of the cold storage panels

Connection of Cold storage panel

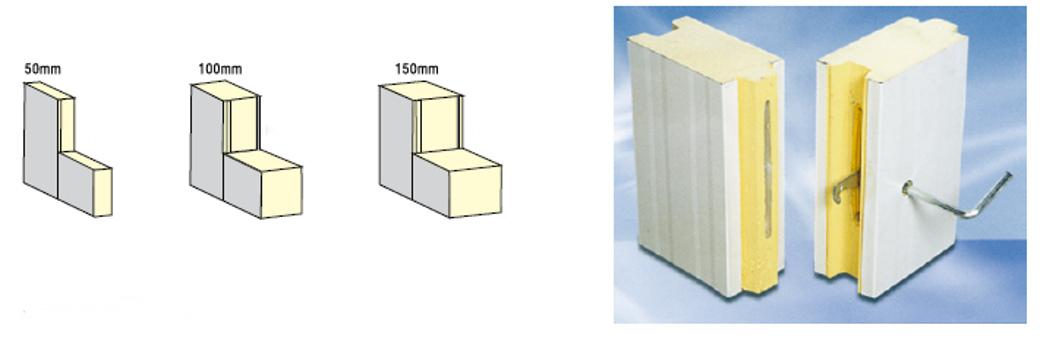

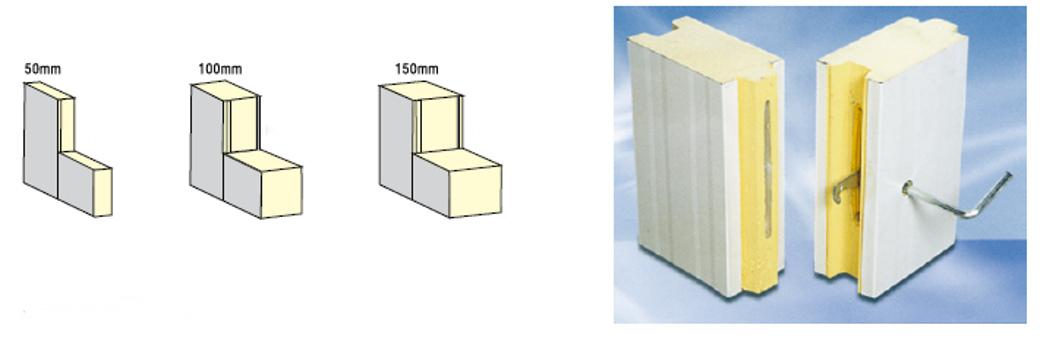

Handmade cold storage panel is handcrafted cam lock panels, these panels incorporate a tongue-and-groove system and are additionally reinforced with cam locks inside, providing extra durability.

Connection of handmade cold storage panel

Handmade cold storage panel is handcrafted cam lock panels, these panels incorporate a tongue-and-groove system and are additionally reinforced with cam locks inside, providing extra durability.

Connection of mechanized cold storage panel

The mechanized cold storage panel is automated integrated panels. These panels are produced using automated machinery, and the joints are equipped with an integrated tongue and groove interlocking system to ensure a tighter bond between the panels.

Today, we analyzed two types of production methods in the fields of clean room panel and cold storage panel, namely handmade sandwich panel and mechanized sandwich panel, so that designers and owners ca n be more targeted in their choices and our products can better meet our requirements.