Refrigeration Principles of Cold Storage

In a cold storage, the stored goods are cooled, frozen and refrigerated in a low-temperature environment, while constantly releasing heat. In order to maintain the temperature, heat needs to be continuously transferred from the inside of the cold storage to the outside – this requires artificial mechanical refrigeration.

The basic refrigeration principles of cold storage is based on thermodynamics and heat transfer, and mainly adopts a vapor compression refrigeration cycle, the main principle of which is heat dissipation.

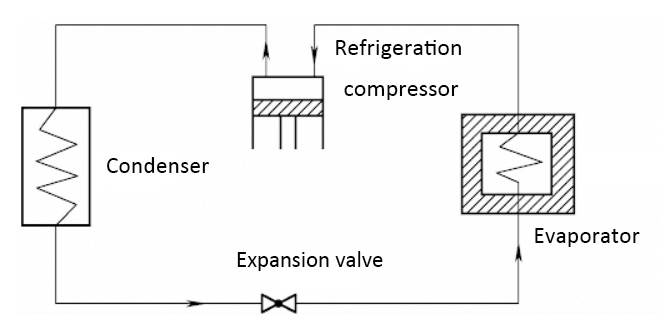

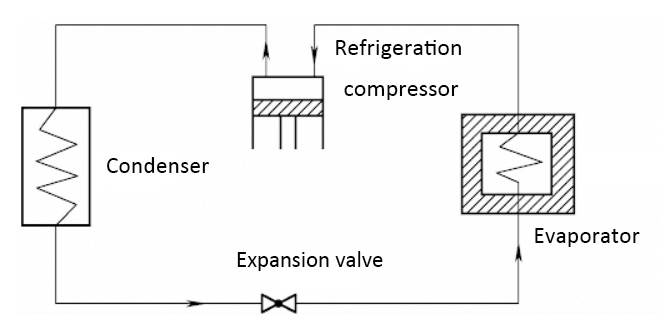

Four Phases of the Vapor Compression Refrigeration System Cycle

The vapor compression refrigeration system consists of a compressor and refrigeration equipment, which are interconnected through various pipes. In the system, the refrigerant circulates continuously to ensure that the refrigeration process is uninterrupted, and the vapor compression refrigeration cycle Completes the closed loop cycle through four stages.

Compression

Electricity is used to drive a cold room compressor to compress a gaseous refrigerant, converting a low-pressure gas into a high-temperature, high-pressure gas, thereby increasing its pressure and temperature.

Condensation

High-pressure hot vapors flow through the condenser (outside the freezer). Air or water cools the refrigerant, causing it to condense into a high-pressure liquid and releasing latent heat to the environment. In this process, the heat of the cold room and the energy of the compressor are removed.

Expansion

The high-pressure liquid flows through an expansion device (e.g. thermostatic expansion valve/TXV, capillary tube). The pressure drops dramatically, resulting in partial flash evaporation and cooling of the mixture to a low-temperature, low-pressure liquid-gas mixture.

Evaporation

The cold refrigerant enters the evaporator (located inside the cold room). It absorbs heat from the air circulating in the cold room and then evaporates the low-pressure, high-temperature liquid from the throttle valve into a gaseous state to lower the temperature of the surroundings.

Key Components in a Cold Storage Refrigeration System

A refrigeration system basically consists of four basic components: a refrigeration compressor, a condenser, a throttle valve and an evaporator. In order to improve the efficiency and effectiveness of the refrigeration operation, a variety of equipment is also added, such as oil separators, intercoolers, liquid storage, auxiliary liquid storage, low-pressure circulating liquid storage, ammonia separators and control valves and so on.

Cold Storage Components

Cold Storage Components includes five parts: Insulation system, Air Circulation system, Temperature Control system, Defrost System, Defrost System.

Insulation system

The insulation system consists of cold storage wall panels, ceilings and floors, all of which are insulated with high R-value insulation (e.g. polyurethane foam) to minimize the entry of external heat and create a tightly insulated space.

Air Circulation system

Fans are arranged at various locations in the cold room to blow cold air from the evaporator coils to the stored products, ensuring an even temperature distribution.

Temperature Control system

Setting up a thermostat in a cold room allows you to monitor the cold room temperature and cycle the compressor on/off to maintain the set temperature based on the room temperature.

Defrost System

Moisture in the air/product triggers condensation on the evaporator coil. This can reduce the efficiency of the evaporator. The use of electric heaters, hot gas bypass or reverse cycle measures automatically defrosts the evaporator and melts the ice regularly, thus ensuring the proper functioning of the evaporator.

Sealing system

Both the door and the seal are part of the sealing system. When the door is closed, the hermetic seal minimizes the infiltration of hot and humid air. The use of seals in cold storage wall panels, ceiling maintenance components also minimizes the infiltration of outside air.

The above is a simple refrigeration principles of cold storage. From here we can understand the more complex cold storage design and construction process. If you are interested in cold storage, you can contact SDpanel.