Comparison between interior wall cassette and sandwich panel

In industrial and commercial facilities, designers have two design options for cladding and wall systems: interior wall cassette and sandwich panel Each option has its own advantages and different applications. This article will explore the core differences, advantages, and disadvantages of interior wall cassettes and sandwich panels in detail.

Fundamental Construction & Core Concept

Internal wall cassette

- Structure: Think of these as highly pre-fabricated, open-backed wall frames. They typically consist of structural studs (often steel or timber), pre-installed insulation within the stud cavities, pre-routed chases for MEP (Mechanical, Electrical, Plumbing) services, and frequently pre-installed sheathing (like plasterboard/gypsum board, OSB, or cement board) on one or both faces.

- Characteristics: They are essentially a pre-assembled “skeleton” of a wall, incorporating core components, ready for final finishing touches like plastering, painting, or cladding on-site. They form a structural or non-structural partition system.

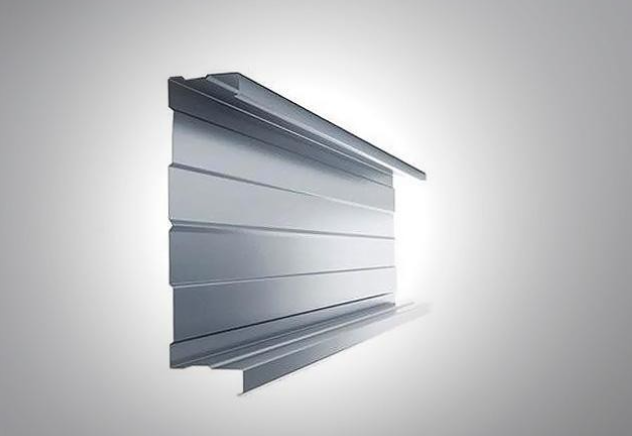

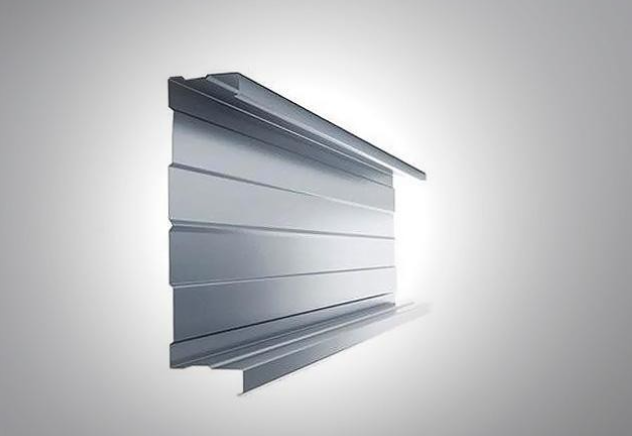

Sandwich Panel

- Structure: :It is a type of multi-layer structural cladding system that consists of two thin and strong metal sheets attached to a substantiating core material. The metal sheets are coated with a corrosion-resistant coating and the core material is usually polystyrene, polyurethane, rock wool.

- Characteristics: They are complete, single-piece panels delivered as finished wall elements. The facing provides a finished surface, eliminating the need for additional cladding or render in most cases. They are primarily non-structural infill panels.

Installation of interior wall cassette and sandwich panel

Internal wall cassette

The cassette panels are hoisted and fixed into place. While they already have extensive pre-installation work (insulation, cladding, notches), significant on-site work remains. This includes installing the mechanical and electrical equipment into the pre-wired notches. If only one side is pre-installed, a second layer of cladding is installed. The cladding surface is taped, jointed, plastered, and finished. Finally, the final finishes (paint, tiles, etc.) are installed.

Cassette panels are quicker to install than conventional construction, but slower than sandwich panels due to the remaining finishing steps. They offer flexibility for complex mechanical and electrical wiring (MEP) during installation.

Sandwich Panel

Sandwich panel is hoisted or transported into position by crane and fastened directly to the building’s structural frame using specialized profiles and fasteners. The joints between the panels are sealed. If the selected finish is final, the wall is essentially complete after fastening and sealing.

Sandwich panel is extremely fast to install. Once the panels are fastened and sealed, the wall system is complete. Structural frame alignment is critical. Mechanical and electrical integration requires careful pre-planning.

Flexibility & Aesthetics

Internal wall cassette: Highly flexible for complex geometries, curves, and intricate MEP layouts. Easier to modify on-site or make future alterations. Offers a wide range of aesthetic finishes through standard plastering and painting or cladding.

Sandwich Panel: Best suited for large, flat surfaces. Modifications post-installation are difficult and compromise integrity. Aesthetics are defined by the pre-finished facing – limited to available finishes (colors, textures of metal, HPL, etc.). Offer a clean, modern, often industrial look.

Cost of interior wall cassette and sandwich panel

Internal wall cassette: Higher initial material cost than basic studs/insulation but lower than premium sandwich panels. Overall project cost depends heavily on the labor required for the remaining finishing work.

Sandwich Panel: Higher upfront material cost, especially for panels with mineral wool cores or high-end facings. Significantly lower installation labor costs due to speed and fewer trades involved. Potential savings in overall project schedule.

Conclusion

The choice between interior wall cassette and sandwich panel is not a matter of which is generally better, but rather which is more suitable for specific project needs. If project installation speed is critical and large, simple partition layouts and durable prefabricated surfaces are required, then choose sandwich panel. If complex geometries, curves, or complex electromechanical wiring are required; if future flexibility or adaptability is crucial; if lower material costs are desired and more construction time is tolerated, then choose Internal wall cassette.