Applications of Acoustic Sandwich Panel

In modern life, amidst the clamor and commotion of cities, people seek quiet environments. Acoustic sandwich panel serves as the primary material for creating serene spaces. Today, we explore the applications of acoustic sandwich panel.

What is an Acoustic Sandwich Panel

Acoustic sandwich panel, as the name suggests, are sandwich panels designed to absorb sound waves and reduce noise transmission through walls. They still employ a “sandwich” structure, but their specific components undergo special treatment to control sound.

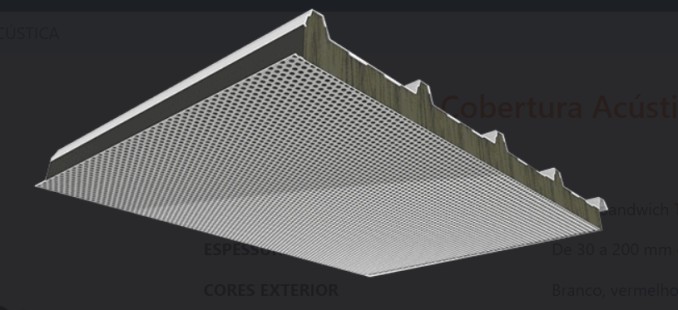

Perforated Facing (Acoustic Passage): The key distinction between acoustic panels and standard insulation boards lies in their perforated outer layer. This facing is typically crafted from steel, aluminum, or wood, featuring a precise array of micro-perforations. These perforations are not defects but acoustic passages. They enable sound waves to penetrate the panel surface and reach the sound-absorbing core, rather than simply reflecting back into the room.

Porous Acoustic Core: The core of acoustic panels consists of an acoustic material core, typically made from mineral wool or glass fiber. This core material is meticulously engineered to exhibit high porosity, forming a labyrinth of microscopic air channels. When sound waves enter this matrix, friction between air particles and the narrow fiber walls converts acoustic energy into negligible heat, thereby effectively dissipating sound.

Solid Backing Sheet: Its rear surface is typically a solid, non-perforated panel. This layer serves a dual purpose: it provides structural rigidity and acts as an acoustic barrier, preventing any residual noise from fully penetrating the panel.

The combination of these three components creates a composite material that is lightweight, structurally robust, thermally insulating, and offers exceptional sound absorption.Acoustic sandwich panels are categorized into three types based on their location: acoustic wall sandwich panels, acoustic roof sandwich panels, and acoustic ceiling panels. In practical applications, acoustic wall sandwich panels and acoustic ceiling panels are more commonly used, often in locations requiring quiet. Acoustic roof sandwich panels are less commonly used because acoustic ceiling panels are typically used for sound absorption. Roof panels are exposed to the elements, requiring higher strength and rigidity, making their selection more cautious. Thinner acoustic wall sandwich panels can be used for acoustic ceiling panels.

Applications of Acoustic Sandwich Panel

The application scope of acoustic sandwich panel spans from large industrial parks to the most intimate personal spaces.

Educational facilities

In classrooms, lecture halls, and cafeterias, excessive reverberation can make it difficult for students to understand lectures. Acoustic wall panels and ceiling treatments ensure clear speech intelligibility, allowing learning to proceed undisturbed by noisy environments. Rock wool acoustic metal panels are suitable for classrooms, auditoriums, and other educational facilities, helping to create a more conducive learning environment for students.

Public Buildings

Public Buildings. Acoustic sandwich panels are essential materials in public facilities such as libraries and community centers—places where quiet is paramount. In these high-traffic areas, they play a vital role in reducing noise transmission and enhancing the acoustic quality of spaces. This creates a more welcoming and comfortable environment for visitors.

In manufacturing, energy, and processing plants, noise is an unavoidable byproduct of operations. This is not merely a matter of comfort but a critical issue concerning regulatory compliance and worker safety.

Industrial Noise Control

Acoustic sandwich panels are the material of choice for constructing machine enclosures and operator cabins. By creating an “enclosed space” around high-noise compressors, generators, or pumps, these panels suppress deafening noise at its source, protecting employees from hearing damage. On a larger scale, they serve as sound barriers and fencing along highways and around industrial zones, shielding residential areas from the constant assault of traffic and industrial noise pollution.

Healthcare facilities

Perforated metal panels are ideal for hospitals, clinics, and other medical institutions to reduce noise transmission and enhance acoustic quality within spaces. Quiet environments significantly benefit the recovery process. In hospitals, these sandwich panels are installed in waiting areas, patient rooms, and corridors to absorb the clatter of equipment, hushed conversations, and the sound of rolling beds. This helps reduce patient stress and improves treatment outcomes.

In short, acoustic sandwich panels are far more than just a simple building material. They are sophisticated, multifunctional tools that ingeniously address one of modern society’s most prevalent challenges. By seamlessly integrating structural performance with advanced sound absorption capabilities.