Application of cold storage panel in pharmaceutical coldroom

Pharmaceutical coldroom is a specifically cold room designed to store medical products, especially those that are sensitive to temperature fluctuations such as vaccines, blood products and biological materials. Compared to standard cold rooms, pharmaceutical coldroom has more stringent requirements for temperature, humidity and air quality management. The core of any modern and compliant pharmaceutical cold room contains a critical but often underestimated component: the cold storage panel. These carefully designed structures are more than just walls, they are the main barrier against external environmental fluctuations, safeguard product stability and ensure compliance with strict Good Distribution Practices (GDP) and Good Manufacturing Practices (GMP).

The demands of pharmaceutical coldroom

Based on the characteristics of refrigerated products, the pharmaceutical coldroom is a combination of a cold room and a clean room. It not only has special requirements for temperature control and humidity control, but also has certain requirements for air cleanliness and bacteria level.

Precise temperature control

Pharmaceutical coldroom often require very tight temperature ranges (e.g., 2°C to 8°C, -20°C, or even -70°C for mRNA vaccines) with very tight deviations (typically ±0.5°C tolerance in critical areas). Temperature fluctuations can cause product degradation, rendering it ineffective or unsafe.

Seamless Construction

Based on the control of humidity and temperature in the pharmaceutical cold room, the tongue and groove design of the cold storage panel ensures tight airtightness. Air leakage and thermal bridges are absolutely not allowed. Continuous airtight sealing is essential to prevent energy loss, moisture infiltration (causing condensation and ice), and temperature fluctuations.

Hygiene & Cleanability

Pharmaceutical cold room requires that both the partition panel and the wall panel and the ceiling panel should be smooth and non-porous, easy to clean and disinfect, which is essential to maintain the sanitary conditions of the pharmaceutical cold room. And help prevent microbial contamination and ensure the safety of drugs.

Durability and Longevity

Pharmaceutical cold room need to operate 24/7 for many years, and cold storage panels are designed to withstand the harsh cold storage environment, including temperature fluctuations and potential condensation, thermal cycling, physical shock and cleaning agent erosion, and maintain performance for decades. Its rugged structure ensures long-term durability and minimizes maintenance needs.

Design of cold storage panel for pharmaceutical coldroom

The requirements for the cold storage panel of the Pharmaceutical cold room are higher than those of ordinary cold storage. It adopts a sophisticated multi-layer system, which is designed to meet the stringent standards of the Pharmaceutical cold room.

Core insulation material for cold storage panel

At present, there are two main types of cold storage panels used in Pharmaceutical coldroom: PIR cold storage panel and PU cold storage panel.

PIR cold storage panel:The dominant choice for pharma. Offers the highest R-value per inch among rigid foams (typically R-7 to R-8 per inch), excellent fire resistance (low flame spread, low smoke density), good dimensional stability, and low vapor permeability. Its superior thermal efficiency directly translates to significant energy savings and enhanced temperature stability.

PU cold storage panel: Historically common. Good insulation (R-6 to R-7 per inch) but generally slightly less efficient and fire-resistant than PIR. Can be a cost-effective option for less critical areas.

Metal Skins of cold storage panel

The outer skin of the Cold storage panel mainly considers its durability and hygiene. The Pharmaceutical cold room is a long-term facility, and the outer skin of the Cold storage panel needs to consider its corrosion resistance and lifespan. Choosing a clean and easy-to-disinfect outer skin is a special requirement of the pharmaceutical industry.

Pre-coated galvanized steel (PPGI/PPGL): The standard choice for general pharmaceutical cold rooms. It is durable, corrosion-resistant, and offers a hygienic and easy-to-clean finish (usually bright white or light-colored). Pre-coating (polyester, polyvinylidene fluoride, polyurethane) enhances chemical resistance to cleaning agents.

Stainless Steel: Used in ultra-hygienic environments (e.g., sterile product handling areas within cold rooms), cleanrooms, or where extreme chemical resistance is needed. Higher cost but unparalleled cleanability and corrosion resistance.

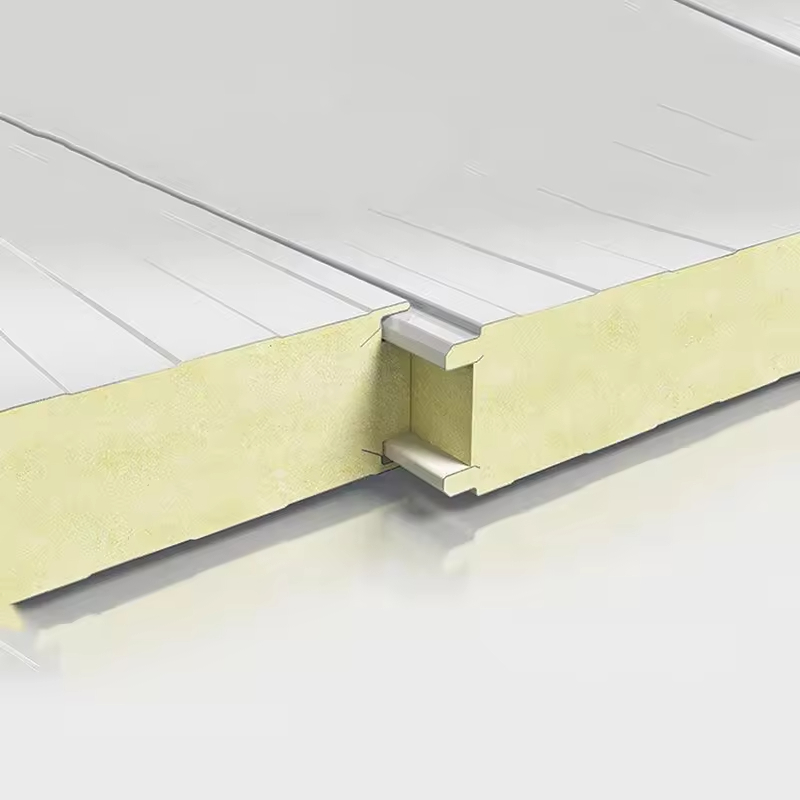

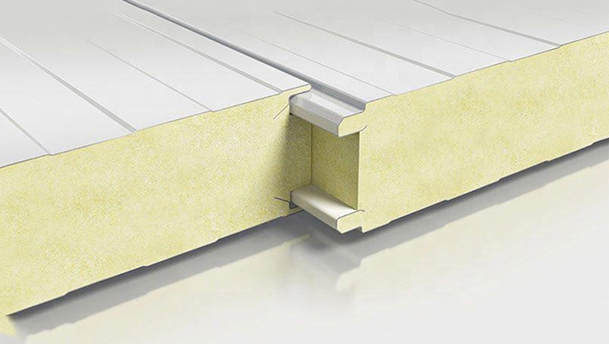

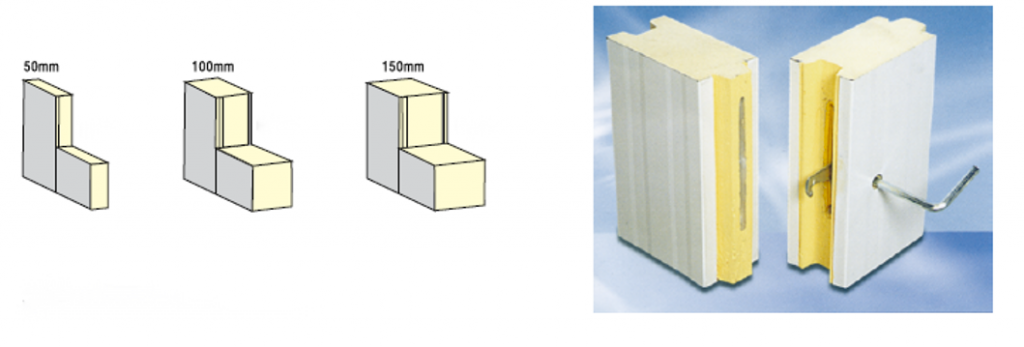

Joint design of cold storage panel

There are two main joint designs for cold storage panels: Tongue-and-Groove Joints and Cam-Lock Mechanisms. Different joint methods are selected according to different cold storages.

Tongue-and-Groove Joints: Tongue-and-Groove Joints: The edges of the panels are made into male and female grooves, which are inserted like building blocks, and then sealed with sealant. This type of joint can be made almost invisible, and there is no cold bridge effect. High-end food cold storage or pharmaceutical cold room prefers it, after all, the temperature difference fluctuation can be controlled within 0.5℃.

Cam-Lock Mechanisms: Integrated metal cams provide powerful, uniform compression along the joint length when tightened, creating a continuous, airtight, and thermally broken seal. This is critical for preventing thermal bridging and air/moisture infiltration.

Selection of cold storage panel for pharmaceutical cold room

According to the above requirements of Pharmaceutical cold room, we can choose the cold storage panel according to the following indicators.

Temperature Requirements: Specify the necessary core thickness and type of insulation (PIR cold storage panel is highly recommended for critical drug storage). The thickness of the core determines the effectiveness of the insulation; the thicker the thickness, the better the insulation, but also the higher the cost.

Hygienic Design: The skin thickness and coating treatment (PE, PVDF) and thickness of the cold storage panels need to be specified to ensure the durability and hygiene of the cold storage panels. The use of stainless steel may be mandatory in certain areas.

Quality of Jointing System: For pharmaceutical cold room, the tongue and groove design is preferred to ensure the overall sealing, but of course, attention should be paid to the quality of the installation; if the deadline is tight, you can choose the fast cam-lock systems. The quality and compatibility of the sealant needs to be verified.

Conclusion

The application of cold storage panels in pharmaceutical cold rooms is not merely a construction choice; it’s a critical factor in ensuring product quality, patient safety, and regulatory compliance. Their superior insulation, ease of installation, and hygienic properties contribute to efficient and reliable cold storage.

By carefully selecting the right cold storage panel and taking design considerations into account, pharmaceutical companies can ensure that cold rooms are built to meet stringent regulatory requirements, maintain product integrity and minimize operating costs.