Calculation of PIR cold storage panels thickness

In our abundant lives, cold storage facilities play an indispensable role in preserving the freshness of our food. The critical barrier within these facilities is provided by cold storage panels, with PIR cold storage panels being the most commonly used type. So, how do we determine the thickness of PIR cold storage panels? What factors influence the thickness of PIR cold storage panels?

PIR cold storage panels thickness calculation

In cold storage applications, PIR cold storage panels with low thermal conductivity offer the best insulation performance. The thickness of cold storage panels can be determined based on a maximum heat flux value of 10 W/m², calculated as follows:

Where H= Thickness of insulation material(m)

λ=Core material thermal transmission coefficient (W/mK)

=Internal and external temperature difference (℃)

Q=Thermal Flow(Recommended value:10 W/m2)

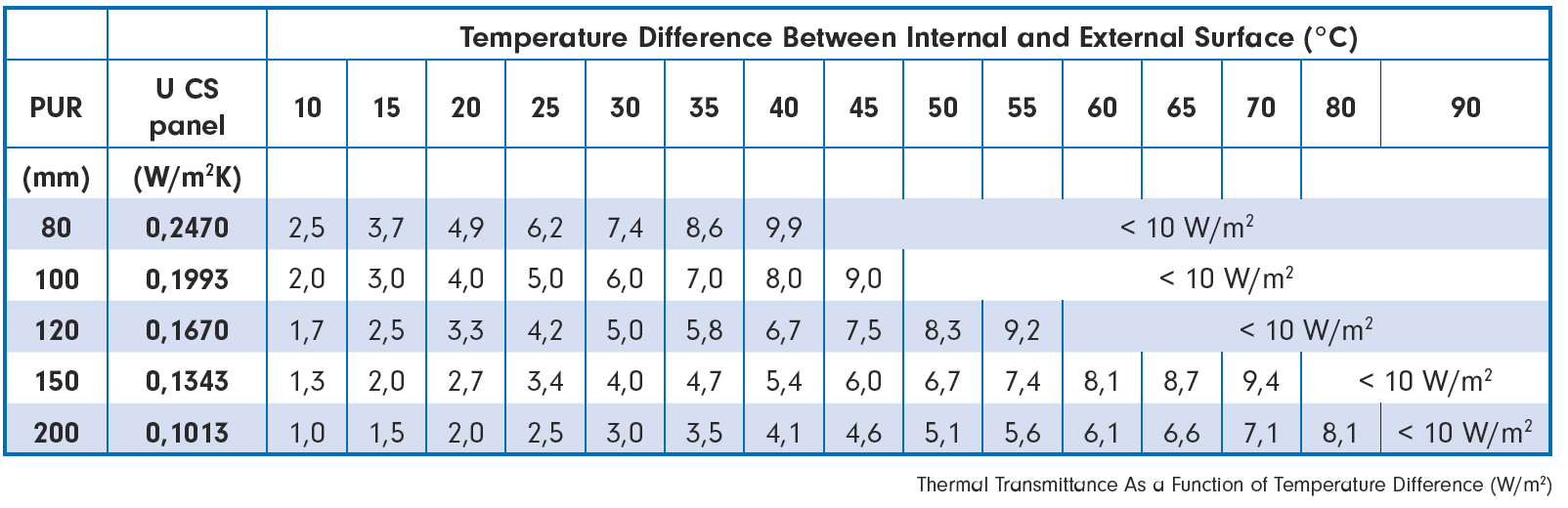

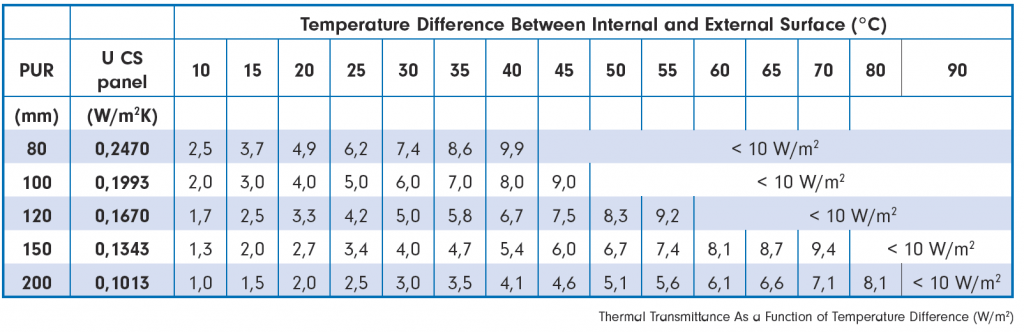

Furthermore, the thermal flow dependent to the PIR thickness and temperature difference is given in Table where SDpanel PIR cold storage panels thermal insulation values are listed. Optimum PUR thickness can be determined according to the values where thermal flow is under 10 W/m2.

PIR Cold Storage Panels Thickness Calculation Example

Scenario: Calculate the thickness for a PIR panel for an industrial freezer maintained at -25°C, located in a climate where the design external temperature is 30°C.

The Temperature Differential: ΔT= 30°C-(-25°C) = 55°C。

PIR thermal transmission coefficient: λ= 0.024 W/m·K

Thermal Flow: Q= 10 W/m2

=

=0.132m

According to the calculated value and the table, a thickness of 150mm can be selected, where the Q value is lower than 10 W/m2.

Factors affecting the thickness of PIR cold storage panels

The thickness of cold storage panels depends on many factors, and the same is true for PIR cold storage panels.

- Temperature difference between the interior and exterior of a building The external temperature of a building is related to its geographical location, while the internal temperature depends on the cold storage facility’s function. Cold storage facilities with different functions have varying internal temperatures.

- Cooling system design Although PIR cold storage panels are airtight, the connection points and accessories still need to be carefully evaluated during the design phase, otherwise freezing may occur. During the design process, the cold storage panel connections and accessories are still carefully designed.

- Comprehensive cost considerations The main consideration is the comparison between energy prices and construction costs. If the energy price is high, the thickness of the PIR cold storage panel can be increased accordingly; if the local energy price is low, the thickness of the PIR cold storage panel can be reduced. This can reduce the overall operating cost of the cold storage.

Conclusion

Calculating the thickness of PIR cold storage panels requires consideration of thermodynamics, materials science, structural engineering, and a comparison of engineering costs versus operational costs. By systematically analyzing temperature differentials, material properties, local climate conditions, and long-term costs, engineers can determine the appropriate panel thickness to ensure refrigeration facilities operate efficiently, reliably, and cost-effectively for decades to come.