Clean room panel

Clean room panel system

Some industries have very high requirements for the cleanliness of space. Clean room technology according to customer requirements for particles, hazardous air, bacteria and other pollutants for effective control, to meet the product processing and experimental research of precision, miniaturization, high purity, high quality and high reliability and other aspects of the needs of the semiconductor, photo electricity, biomedical, fine

chemical industry, aerospace and aviation, food processing and other industries have been widely used.

Solideck is an industry leader in clean room panel system design, material technology and manufacturing process, providing customers in specialized fields with comprehensive solutions for clean room narrow enclosure with unique value.

Categories

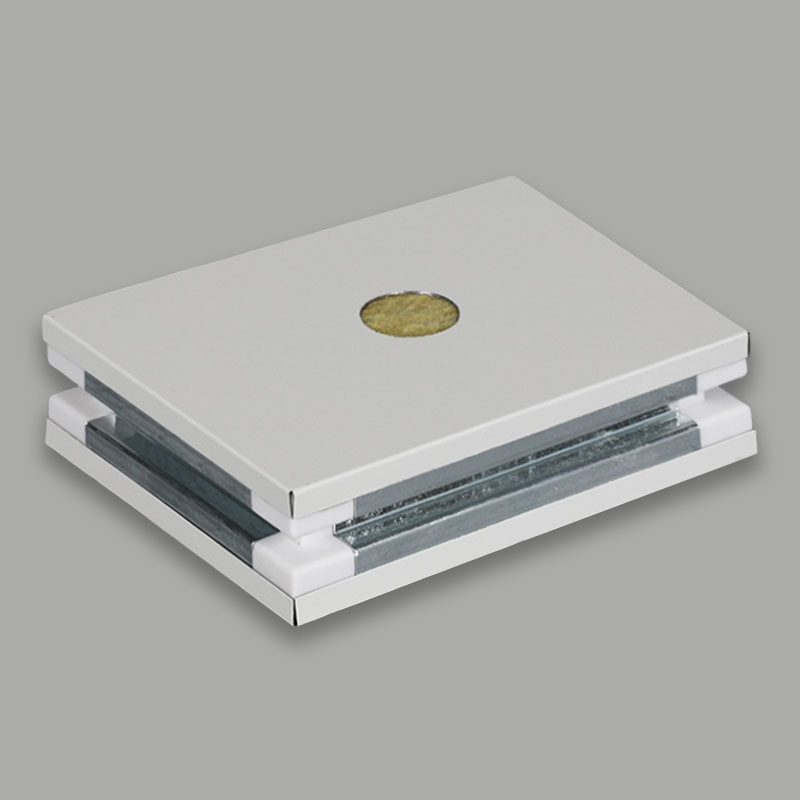

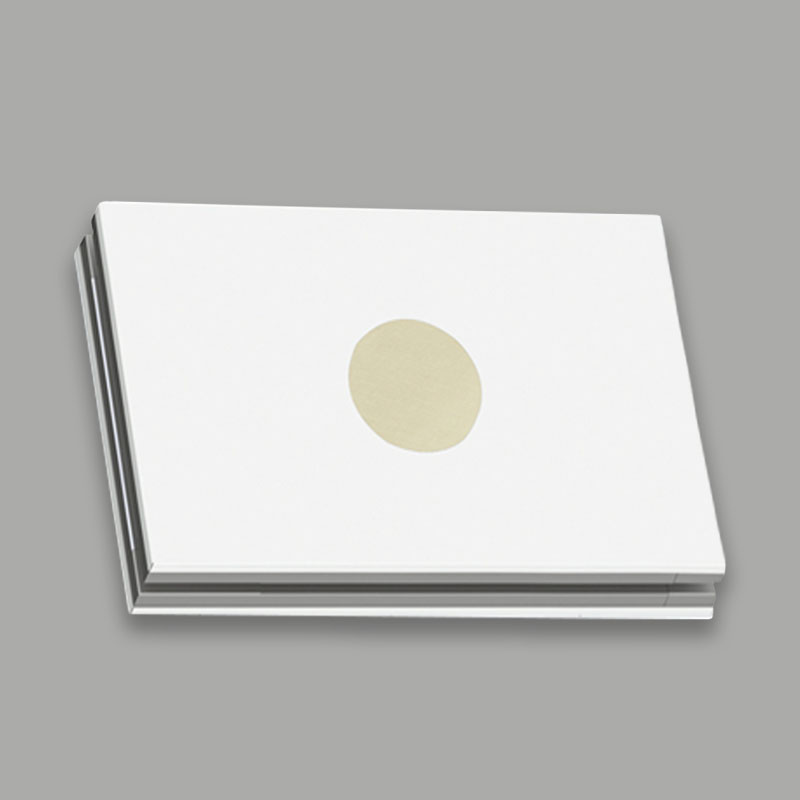

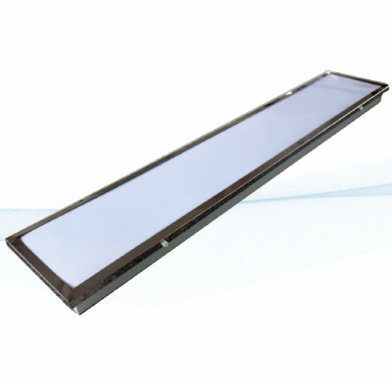

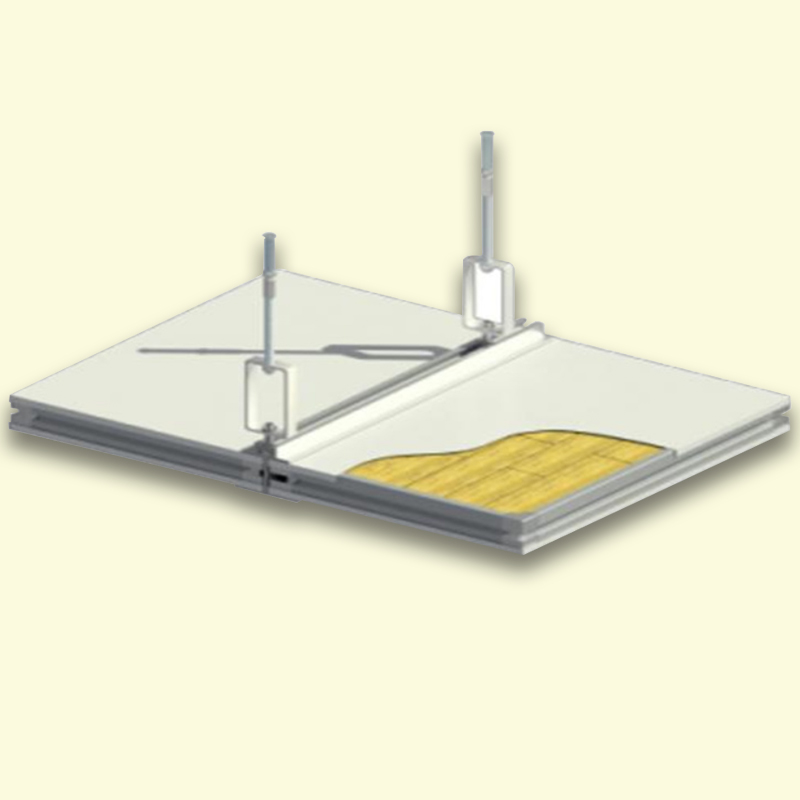

Clean room Ceiling panels

SDpanels’ clean room ceiling panels have strong sealing and walkability, and excellent strength and bending resistance. And the gap width is exactly the same to ensure the appearance of the clean room.

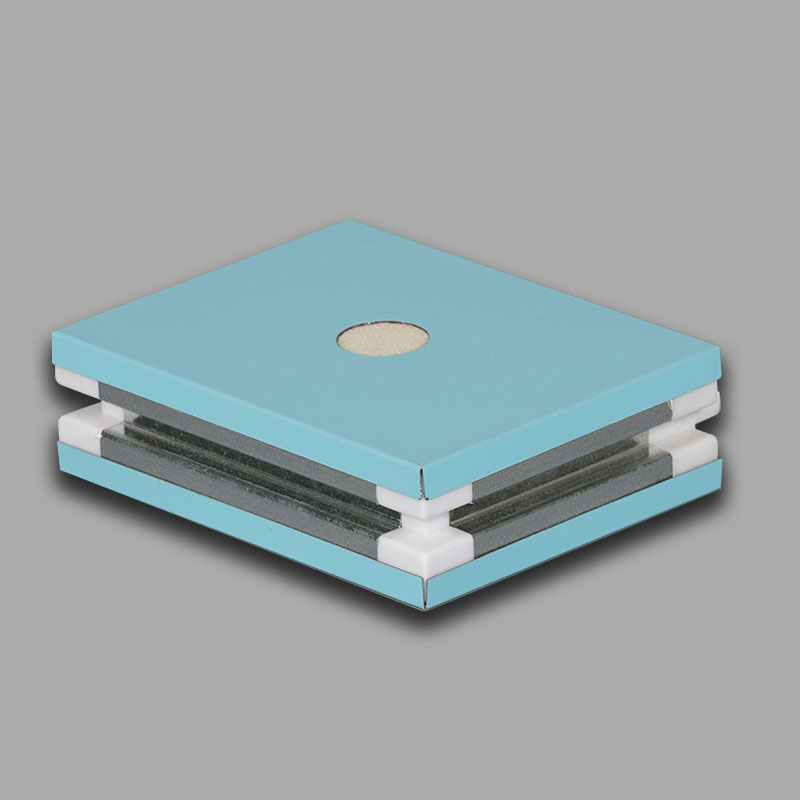

Clean room Partition panels

SDpanel’s clean room partition panels not only meet the functional requirements of building preservation, heat preservation, flatness, and anti-deformation, but also have excellent energy-saving, environmental protection , while creating a unique aesthetic for the building.

Clean room Doors&Windows

SDpanel clean room doors &Windows widely used in cleaning workshops, hospitals, pharmaceutical factories, food factories, etc ,it has good performance at outside facer,flat ,high structural strength, corrosion resistance, no dust, easy to clean .the most important is easy installation .

Products

Clean room door

“Clean room door” refers to a door used in a clean room or dust-free environment. It is designed and manufactured to ensure the cleanliness and sealing of the indoor environment. Clean room doors usually have the following characteristics:

- High sealing: The structure and materials of the clean room door ensure high sealing performance and prevent external contaminants from entering the clean room.

- Antibacterial material: Use antibacterial and dust-resistant materials for easy cleaning and maintenance.

- Corrosion resistance: Use corrosion-resistant materials and coatings, suitable for various chemical environments.

- Automation function: Many clean room door is equipped with automatic switches and sensors to reduce human contact and further reduce the risk of contamination.

- Fireproof performance: Some clean room door also has fireproof functions to improve safety.

Clean Room Window

SDpanel clean room window widely used in cleaning workshops, hospitals, pharmaceutical factories, food factories, etc ,it has good performance at outside facer,flat ,high structural strength, corrosion resistance, no dust, easy to clean .the most important is easy installation for your projects.

SDpanel’s modular clean room windows are double-glazed, installed flush with the surface of clean room wall panels, beautiful and easy to clean. Each unit consists of two 5 + 5 mm laminated safety glasses. Aluminum alloy reinforced keel, internal hollow processing, built-in 3A molecular sieve, optional argon filling, to prevent internal fogging.

The clean room window has three thicknesses: 50 mm, 75 mm, and 100 mm. The keel of the window is made of aluminum alloy. The glass is made of tempered glass, ultra-white tempered glass, and fireproof glass. 3 A molecular sieve is built into the glass and can be filled with inert gas.

The transfer window is made of stainless steel plate, smooth and smooth. The double doors are interlocked with each other to effectively prevent cross contamination, with electronic or mechanical interlocking device, and equipped with ultraviolet germicidal lamp. Transfer window is widely used in micro technology, biological laboratory, pharmaceutical factory hospital, food processing industry, LCD, electronic factory and other places.

Clean Room Equipment

Accessories

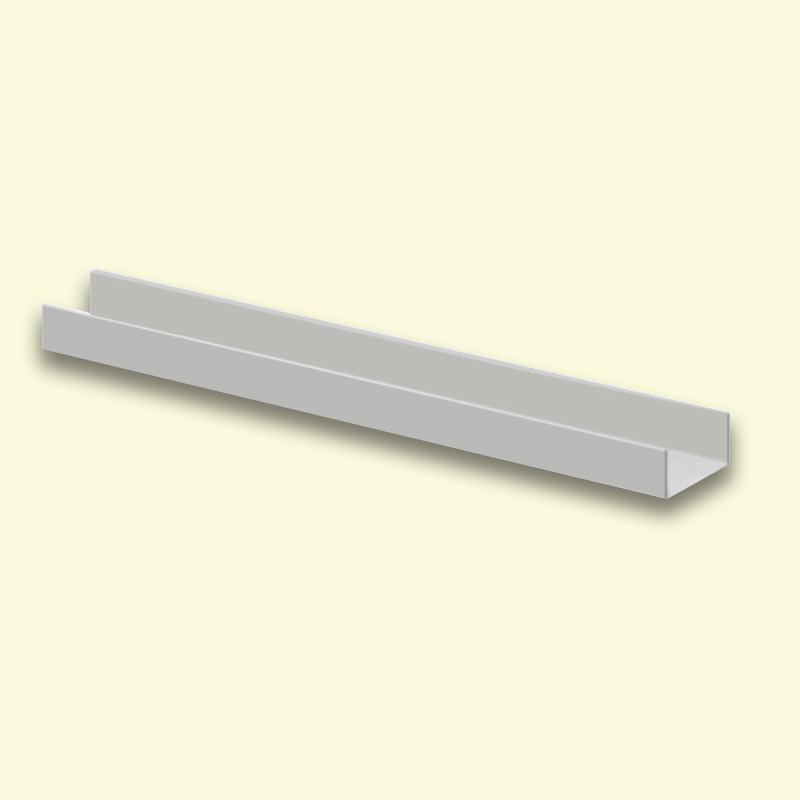

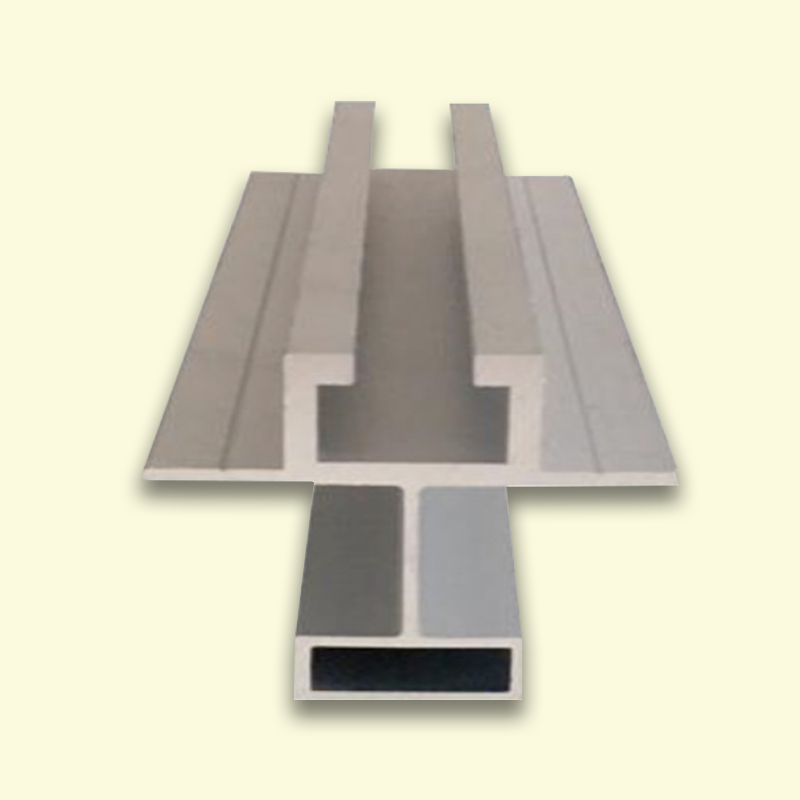

U-shaped groove

Interior Corner End

Corner fittings

Screw

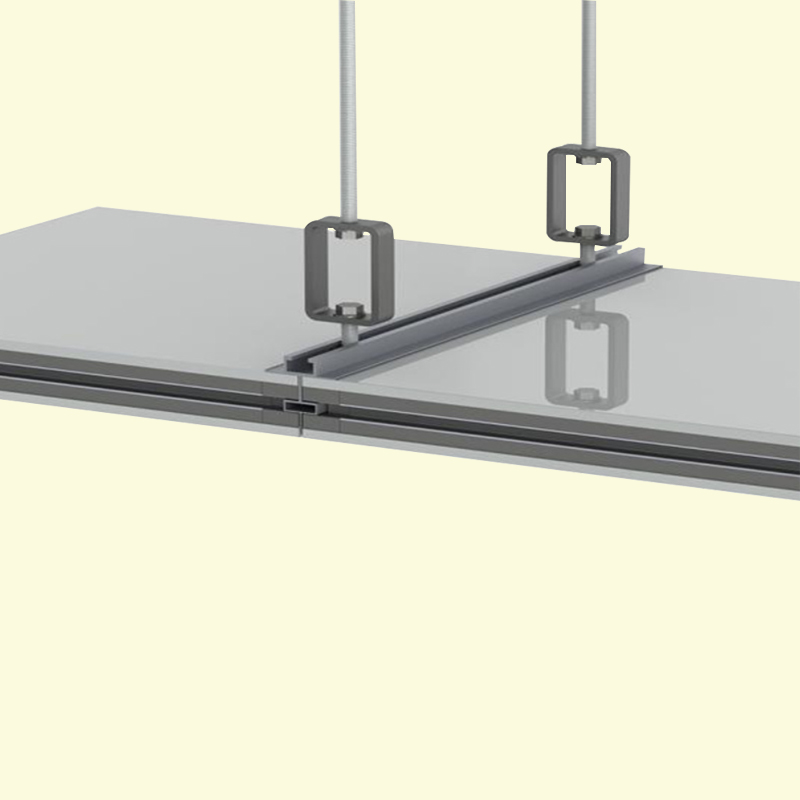

T-Grid Steel Ceiling

Non-cold bridgeCeiling

I-Grid Steel Ceiling

C-Grid Steel Ceiling

Frequently Asked Questions

A cleanroom is a meticulously controlled environment designed to minimize the presence of airborne particles, microbes, aerosols, and chemical vapors. These rooms are critical in industries where even microscopic contaminants can compromise product quality or research integrity.

Cleanrooms maintain ultra-low levels of particulate matter, such as dust, airborne organisms, or evaporated particles, through advanced engineering, careful design, and strict operating procedures.Four essential features include Air filtration, pressure control ,environmental control and human disciplines.

The size of the clean room panel varies depending on the needs of the client. For ease of construction, most panels are less than 7500mm in terms of length.As for the width, the standard clean room panel will either be 980mm, 1080mm, or 1180mm.The thickness of these clean room panel will generally be 50mm, 75mm, or 100mm.Any other width and length can be custom made from SDpanel.

The cleanroom panels are widely used in various industries, such as IT , semiconductors, food, pharmaceuticals, aerospace, high-tech laboratories, etc.