Semiconductor, optoelectronics, biomedicine, fine chemicals, aerospace, food processing and other industries need to effectively control pollutants such as particulate matter, harmful air, bacteria, etc., in order to meet the needs of product processing and experimental research for precision, miniaturization, high purity, high quality and high reliability. Clean storage is a key measure to effectively control the cleanliness of space. So, what are the specific components of clean room? This article introduces them in detail.

The clean storage system mainly consists of four components: enclosure system, environmental control system, support tool system and The Human Interface system.

Enclosure system of clean storage

Enclosure system of clean storage includes walls and ceilings, partitions and floors.

Walls and Ceilings of Clean Storage

These form the fundamental enclosure, typically constructed from smooth, non-shedding, and easily cleanable clean storagepanel. Common choices include: Rock Wool Clean storage panel, Calcium Silicate panel, PU clean room panel, Glass magnesium panel,etc

Flooring of Clean Storage

Must withstand heavy traffic, chemicals, and rigorous cleaning while being static-dissipative (ESD) in electronics settings. Types include: Raised Access Flooring, Conductive Vinyl Tile, Seamless Epoxy or Urethane Resin.

Clean Storage Door&window

SDpanel clean storage door&window widely used in cleaning workshops, hospitals, pharmaceutical factories, food factories, etc ,it has good performance at outside facer,flat ,high structural strength, corrosion resistance, no dust, easy to clean .the most important is easy installation for your projects.

Environmental control system of clean storage

Environmental control system This is the core of the clean room, which includes HVAC system, pressurization system, temperature and humidity control system.

HVAC System (Heating, Ventilation, Air Conditioning)

Responsible for the cleanroom’s temperature and humidity as well as important air filtration and airflow control.

Air Handling Units

Massive units located outside the cleanroom contain pre-filters, cooling/heating coils, humidifiers/dehumidifiers, and powerful blowers. They condition the air before final filtration.

HEPA/ULPA Filters

High-Efficiency Particulate Air (HEPA) filters capture 99.97% of particles ≥0.3 microns. Ultra-Low Penetration Air (ULPA) filters capture 99.999% of particles ≥0.12 microns. These are the final barrier, typically mounted in the cleanroom ceiling (as FFUs or in a plenum) or sometimes in the walls.

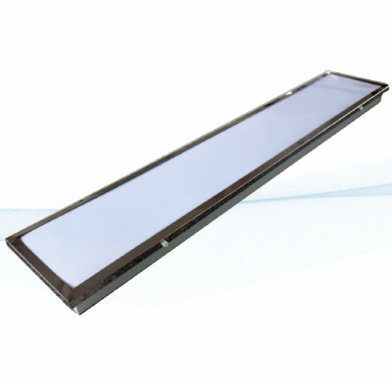

Fan Filter Units (FFU)

Self-contained modules housing a HEPA/ULPA filter and a fan, mounted directly in the ceiling grid.

Pressurization system of clean storage

Clean rooms are maintained at a positive pressure relative to adjacent less clean areas. This prevents contaminated air from seeping in through door gaps or leaks. A cascade effect is often used (e.g. ISO 5 room > ISO 7 anteroom > corridor > outside). Sophisticated control dampers and pressure sensors regulate this.

Temperature and humidity control system

Temperature and humidity control is critical to process stability, operator comfort and preventing static electricity. It is achieved through the coils of the air handling unit (AHU) and the humidification/dehumidification system and maintains tight temperature and humidity tolerances.

Support tool system of clean storage

The support tool system includes lighting, furniture and work surfaces, and other service facilities.

Lighting

Cleanroom lighting is typically airtight and chemically resistant, and provides high-brightness, uniform lighting without generating excessive heat. LED lighting is now standard for efficiency and low heat output.

Furniture & Work Surfaces

Most of these furniture or platforms are made of stainless steel. The design must be simple with rounded edges, no horizontal surfaces that can easily collect dust, and are usually perforated to allow laminar airflow. The seats are made of non-shedding, cleanable vinyl or conductive fabric.

Other service facilities

Other service facilities include transfer windows, power sockets, data ports, process gases (compressed air, nitrogen, etc.), vacuum lines, and deionized water interfaces. Except for the transfer windows, other facilities are integrated into the walls or service columns to ensure the integrity and cleanliness of the cleanroom enclosure. The transfer room transfers items without affecting pressure or cleanliness.

The Human Interface system

The Human Interface system mainly includes Air Showers and Garmenting Rooms.

Air Showers

Enclosed chambers located at personnel entrances. High-velocity HEPA-filtered air jets remove loose particles from garments before entering the main cleanroom.

Garmenting Rooms

Transition zones where personnel don specialized cleanroom attire made from non-linting, static-dissipative fabrics.

Conclusion

Clean storage is seamlessly integrated by the above four systems with perfect performance, and each part serves the single goal of controlling pollution. The composition of clean storagereflects superb engineering technology. Walls, air, lights, equipment and processes are intertwined to create an environment where the air itself is a carefully controlled component, making microchips, life-saving drugs and cutting-edge scientific discoveries on a scale unimaginable in the outside world possible.