Cold Room Panel

Cold Room Panel

For construction solution in refrigerated storage rooms, laboratories, and hospitals, that preserves food and medicines, we recommend our Cold Room Panel due to their negative temperatures reached (up to -30c) that support the preservation of such products.

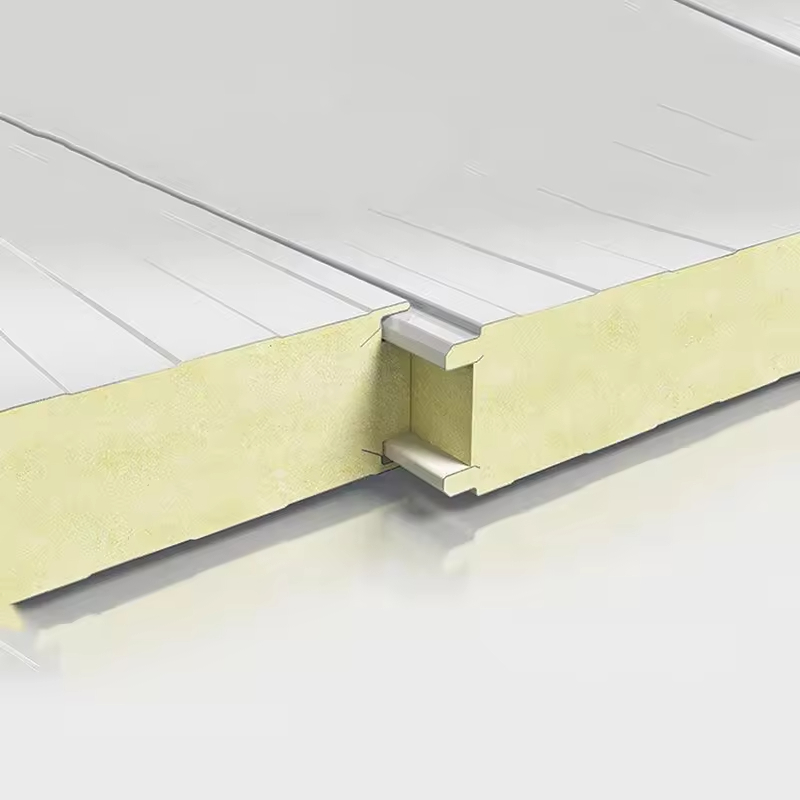

Refrigeration Panels are available in very high thicknesses, up to 200 mm, and reinforced with leak-proof seal. One of our recent data technical updates reads that our frigorific panel has gained 15% more thermal insulation and 10% less cold loss at a lower cost with the perfected joint system, making us the leading provider in the cold chamber market.

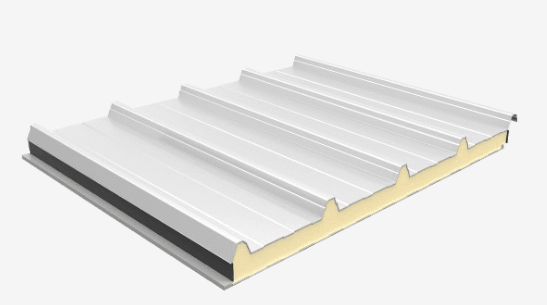

Cold Room Roof Panel

Description for this block. Use this space for describing your block. Any text will do. Description for this block. You can use this space for describing your block.

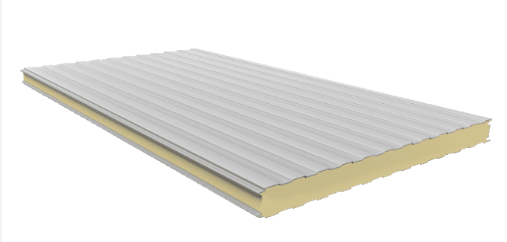

Cold Room Wall Panel

Description for this block. Use this space for describing your block. Any text will do. Description for this block. You can use this space for describing your block.

The classification according to insulating materials

Cold storage panels are essential for maintaining controlled temperatures in refrigeration units, warehouses, and food processing facilities. Their classification is based on multiple factors, each influencing performance, durability, and suitability for specific applications. Here’s the classifications according to insulation materials:

Polyurethane (PU): High thermal efficiency (R-value ~5.6–8 per inch), lightweight, and moisture-resistant. Common in moderate-temperature storage.

Polyisocyanurate (PIR): Improved fire resistance and slightly higher R-value than PUR. Ideal for applications requiring enhanced safety.

Cold Room Door

The main purpose of doors for the cold rooms is the thermal insulation of the doorway through which the products are loaded and unloaded. Therefore, the construction, hardware of cold room door should not have the “thermal bridges”, or reduce them to a minimum. The doors must withstand the temperature conditions and workload in the refrigerated chambers; so it is important, when choosing doors, to select the right type of door and its technical characteristics: size, insulation thickness, etc.

Types of cold room door:

- Hinged cold room door

- Sliding cold room door

- Electric sliding cold room door

- Vertical cold room doors

Hinged cold room door

Hinged Cold Room door designed and constructed to suit the demands of cold storage and the food industry are manufactured with polyurethane foam technology of a high heat insulating level, with a thickness of 60-120 mm depending on the door types, from stainless steel or polyester coated plates. In each case, the doors come with PVC frame structure, and in cold storage temperature range, the doors are fitted with a threshold sunk below the floor level and with built-in heating. Smaller doors and doors used in the medium temperature range are fitted with a frame closing the panel opening, which is extremely simple to put in and is also suitable for covering the cold room panel edge, so there is no need for a counter-frame or for subsequent panel closing when putting in the door.

Sliding cold storage door

SDpanel’s sliding cold storage door is made with the same insulation material as our cold room panel, and feature double-sided color steel plates for durability and strength. Theground part of our doors includes an anti-freezing device, while our electric heatingprotection device ensures safety and prevents leakage.

Electric sliding cold storage door

We’ve incorporated the latest synchronous motor control system to ensure the smoothoperation of the door, making it easy to use for anyone. Our electric sliding cold storage door isdesigned for various industries, ranging from cold storage to freezers and hightemperature warehouses, with an applicable environment range of -60’C to 120°C.

Cold Storage Equipment

Cold storage equipment plays an indispensable core role in the cold storage room. These equipment keep the cold storage room cool so that food, medicine and other products can be better stored.

Cold Storge SDpanel

SDpnel is a leading cold storage metal panel manufacturer that delivers cold storage solutions of many sizes and complexities. We provide refrigeration-insulated and temperature-controlled insulated metal panels that maintain a stable interior environment and protect perishable goods, regardless of the exterior weather conditions.

Your Cold Storage Partner

Cold storage is a critical segment of the global supply chain that provides storage and temperature control for products and materials. Whether food and beverages are going to restaurants, grocery stores, or directly to consumers, cold storage is always in great demand as perishable food products necessitate storage in temperature-controlled warehouses.

Our cold storage metal single-component panels offer air- and water-tight seals that stabilize interior conditions while offering superior energy efficiency and thermal control. Our thermal insulation solutions offer the highest level of hygienic and contamination control to prevent food waste and loss of products due to spoilage. Additionally, our low-maintenance panels are easy to clean and can withstand repeated washes without damage

Why choose insulated SDpanel for cold storage?

Across all product lines, SDpnel’s cold storage panels offer the following benefits for cold storage and refrigerated warehouse applications:

- Superior Insulation: Our panels ensure long-term energy efficiency, which means cost savings for your business.

- Ease of Installation: Faster construction times expedite operational readiness.

- Versatility of design: with the option for horizontal or vertical installation

- High strength-to-weight ratio : allows for greater spans and reduced structural costs

- Cost-Effectiveness: Our streamlined installation process cuts down on labor and complexity

- Impermeable Surfaces: We guarantee optimal temperature and humidity control.

- Antimicrobial surface : prevents bacteria, fungal, mold, and mildew growth

- Tight airtightness: Complete prevention of air and water penetration and leakage

- Complete Environmental Control: Essential for product integrity.

- Low Maintenance: Durable and easy-to-clean, our panels reduce operational costs.

Frequently Asked Questions

Cold storage panels (often referred to as cold room panels or refrigeration panels) are specialized building materials ,are essential components in creating controlled temperature environments for the storage of perishable goods.such as refrigerated warehouses, walk-in freezers, food processing facilities, or pharmaceutical storage units.

Cold room panel combine advanced high-performance insulation core materials, structural design using sealed connections and thermal engineering principles to limit heat transfer, help maintain stable temperatures and reduce energy consumption.

The core is made of rigid foam insulation like polyurethane (PUR), polyisocyanurate (PIR), or polystyrene (EPS/XPS). These materials have exceptional thermal resistance (high R-values), which minimizes heat transfer between the cold room and the external environment

SDpanel’s cold room panel is typically used in facilities such asfood cold rooms, pharmaceutical and medical cold rooms, flower coldstorages, cold chain warehouses, poultry farms, seafood quick-freezefacilities, fruit and vegetable storages, slaughterhouses, meat processingplants, wineries, dairy factories, ice cream companies, beverage plants,quick-freeze tunnels, food processing plants, container cold chain trucks,cold room trailers, and in public areas of hotels, motels, and supermarkets