How to choose the thickness of cold storage panels

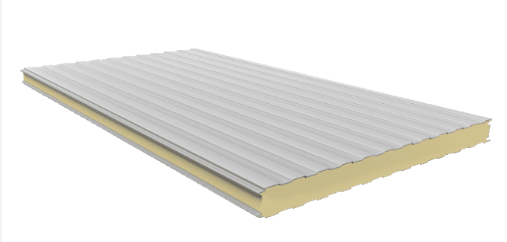

As the enclosure structure of the cold storage, the cold storage panels not only play a role in structural safety, but also plays an important role in thermal insulation for the cold storage. Choosing the right thickness for cold storage panels (insulated sandwich panels) is critical for energy efficiency, temperature stability, and long-term performance. How to choose the thickness of cold storage panels in different situations? Many owners are at a loss. Today, SDpanel will analyze it in detail for you.

The thickness of the cold storage panels are affected by factors such as the temperature of the cold storage, the core material of the cold storage board, structural safety requirements, and the external environment.

Required cold storage temperature

Required Temperature Range is the most critical factor in cold storage panels thickness, which directly affects the insulation performance of cold storage.

Refrigeration room

These refrigeration rooms are mainly used for dairy products, beverages, short-term agricultural product storage, and the temperature range is 0°C to +10°C. The indoor temperature of these cold rooms will not be too low, so the thickness of the general cold storage board is 80–100 mm.

Freezing room

These freezing room are mainly used for frozen food, ice cream, meat storage, and the temperature range is -18°C to -25°C. The indoor temperature of these freezers is lower than that of refrigeration room, so the thickness of the general cold storage panels is 120–150 mm.

Ultra-Low temperature room

These ultra-low temperature room are mainly used for industrial freezing, pharmaceutical storage., and the temperature range is -25°C to -40°C. The indoor temperature of these freezers is lower than that of freezing room, so the thickness of the general cold storage panels is 150–200 mm.

Core material for cold storage panels

Because the insulation value of cold storage panels with different cores is not the same, that if a certain freezing effect is achieved, the thickness required is different.

PU/PIR cold storage panel

Based on its high calorific value; R=0.021-0.023 W/m-K, PU/PIR cold storage panel is the most commonly used in cold storage. Compared to EPS/XPS, PU/PIR cold storage panel is available in thinner thicknesses.

EPS/XPS cold storage panel

Although the cost is lower, due to its lower R-value (R=0.033-0.038 W/m-K), a thicker panel is required to achieve the same insulation effect as PIR/PU cold storage panels.

Structural safety requirements

As different cold storage, its requirements are different, and the requirements of structural safety are also different, these also affect the thickness of the cold storage plate. For example, if the wall is too high then the thickness of the cold storage panel needs to be increased to ensure the stiffness of the wall. If the cold storage has requirements for fire resistance, this will affect the thickness of the PIR cold storage panel.

The external environment

Higher ambient temperatures/humidity (e.g., tropical climates) demand thicker insulation to reduce heat ingress and prevent condensation. In areas with lower temperatures, the thickness of the required cold storage panels will be thinner.

Summarize

Of course, there are many other factors that affect the thickness of cold storage panels, such as thermal bridging effects, the way they are lapped, and how often the door is opened, to name a few. But overall, the more influential factors are: the temperature of the cold storage, the core material of the cold storage board, structural safety requirements, and the external environment.

Owners should work with their suppliers to perform heat load calculations and validate them with actual case studies before proceeding with cold storage design.