What are the factors that affect the life of clean room panels

With the widespread use of clean rooms, people are paying more and more attention to the service life of clean room panels. So what factors affect the service life of clean panels? As a well-known clean room enclosure system service provider in China, SDpanel will explain to you several factors that affect the service life of clean room panels.

Raw materials of clean room panel

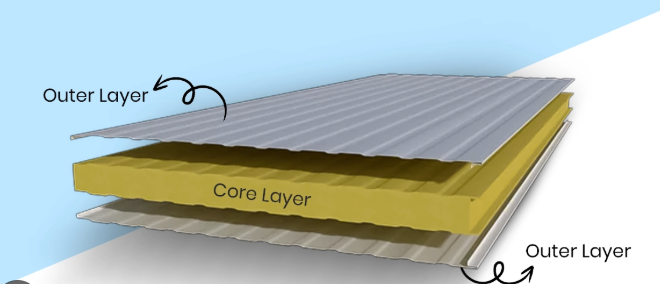

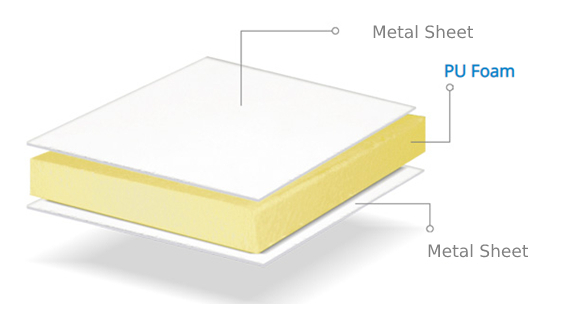

The raw materials for clean board production mainly include: the skin, core material, glue and some auxiliary materials. These raw materials are directly related to the service life of the clean room panel.

The skin of clean room panel

The skin of clean room panel is to protect the core material and provide a cleanable surface.

- PPGI Sheet: Common and durable. Thickness and coating quality (e.g., G300 vs. G550) are critical. Thicker gauges resist dents and damage better. Pre-painted finishes add chemical and corrosion resistance. Quality of the finish affects resistance to chipping, scratching, UV yellowing (for areas with light exposure), and chemical degradation from cleaning agents. We use raw materials from well-known manufacturers such as Baosteel, and their performance indicators are stable and excellent.

- Stainless Steel: Superior corrosion and chemical resistance, essential for harsh environments (e.g., potent compounds, frequent aggressive ecleaning). Maximizes lifespan in demanding applications .

- Aluminum sheet :Aluminum sheet also has strong corrosion resistance, which can ensure the service life of the clean plate in some harsh environments.

Core material of clean room panel

The core material is the core foundation that determines the life of the clean room panel. Among the core materials currently available, rock wool clean room panel has excellent fire resistance and sound insulation performance, and its durability is relatively strong during use. PU clean room panel has excellent thermal insulation performance and lightweight characteristics, and has strong moisture resistance and can have a long service life. Although paper honeycomb is low in cost, it has poor moisture resistance and impact resistance, so its life is relatively short.

Clean room panels equipment and manufacturer

No matter how high-quality the raw materials of the clean room panel are, if the equipment used to produce the clean room panel is old and the machinery is aged, the quality of the clean room panel produced will be unsatisfactory. The production of clean room panels includes multiple procedures. If there is a problem in one procedure or the equipment quality of the procedure is not up to standard, it will cause quality problems of the clean room panel, thus affecting its service life.

SDpanel clean room panel has an advanced automated production line with a production efficiency 4 times higher than that of other companies. The process of panel forming, gluing, core material filling, composite lamination, finished product stacking, etc. are all realized through precise measurement and intelligent control, which greatly improves the accuracy, strength, flatness and aesthetics of the cleanroom panel, makes the product quality more stable, and also ensures the service life of the cleanroom panel.

Clean room panel design

The panel design of the clean room panel also affects its life. A good panel design will make it smoother and more compatible during production and installation.

- Structural Load Capacity: Panels must be engineered to withstand anticipated loads: dead loads (ceiling filters, services), potential live loads (maintenance personnel), and external pressures (differential pressurization). Under-engineered panels risk deflection, joint stress, and premature failure.

- Joint Design: The interlocking mechanism (e.g., tongue-and-groove, shiplap) must ensure a tight, consistent fit. Designs that facilitate proper compression of integrated gaskets are superior. Poor joint design leads to leaks and instability.

- Modularity & Compatibility: Panels need to integrate seamlessly with doors, windows, pass-throughs, lighting, and HVAC systems. Poorly designed interfaces create stress points and potential leak paths, accelerating wear.

Clean room panel installation quality

Even the best panels will perform poorly if not installed properly. The key is to get the horizontal and vertical foundation right, and installers should avoid any errors.

Proper sealing prevents damage to the core. Sealant must be applied meticulously at all penetrations (ducts, conduits), corners, and floor/ceiling interfaces to prevent air and contaminants from infiltrating, which can damage the core over time. Damage during installation (e.g., dents, scratches, core perforations) creates immediate defects and potential contamination points.

Use environment of cleanroom panels

Clean room panel is to determine the environment clean is another important factor in the life of the board, because the use of good or bad will directly affect the environment clean plate life, and thus indirectly affect the clean room life , reducing the clean room class, increase the use of energy, Increase operating costs.

In this environment, extreme humidity and temperature can seriously affect the life of the clean room panel. Strict control of the humidity in the clean room is essential, and maintaining a stable temperature can also extend the life of the clean room panel. Another influencing factor is the exposure of chemicals. If the panel material is not specifically designed for chemical resistance, frequent use of corrosive cleaning solvents, sterilizers (such as VHP) or process chemicals may damage the surface finish, gaskets and sealants. The last thing that affects the life is the vibration of the machine equipment, which loosens the fasteners of the clean panel and damages the integrity of the joint.

Daily maintenance of clean room panels

In order to ensure that the cost-effective clean room panels can maintain a smooth surface and clean appearance for a long time, the clean room panels should be regularly dusted and coated for protection to enhance the life of the clean room panels.

Conclusion:

The service life of clean room panels is not determined solely by the initial product selection. It stems from the complex interaction of many factors such as the cleanroom panel material, panel design, cleanroom panel production equipment, on-site installation capabilities, environment, and daily maintenance. These determine the service life of the cleanroom panel.